Treatment of Slop Oils and Oily Sludges

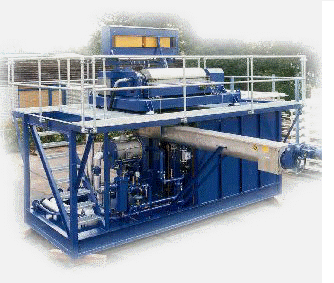

The module

Waste streams in oil refining and production facilities contaminated with excessive sediments are easy to separate from the liquid (oil & water) in a G-force decanter so that the liquid effluent portion can be returned to the refinery oil-water separators. If however after sediments are removed by the 2-phase decanter and the effluent phase (oil & water) need to be separated then the decanter module is to be installed in combination with the G-force MKII or MKIII or MKX Series Plants. The MKD module (pictured left) is built as a plug in module ready to operate, complete with feed pump, effluent pump and sediment conveyor as part of the delivery. The unit is designed to handle a maximum flow rate of 10 m/hr depending upon the feed characteristics and the required result. The unit is designed with the new EU ATEX 2 norm for explosion proof equipment so that it meets compliance regulations for all types Oilfield operations. Hook-up is made easy by having all flanges terminate on one side of the module.

Principle of operation

The decanter features a slender cylindrical/ conical bowl with a relatively large length/ diameter ratio. A characteristic is the screw conveyor fitted inside the bowl for continuous removal of solids as they are plastered and scraped from the inter bowl wall to the discharge ports. Typical bowl speeds are in the 1000-4000 rpm range where particle G force acceleration is up to 3000. Process liquid is fed into the cylindrical section, where it forms a layer consisting of solids to the outer bowl and liquid effluent towards the inter section of the bowl. The thickness of this layer is established by a series of discharge weirs at the end of the cylindrical section, and through which the clarified liquid effluent (oil & water) is decanted. Solids being heavier are plastered against the bowl wall, from where they are continuously removed by the screw conveyor and transported up the conical section, referred to as the beach, and exit through the discharge ports opposite the liquid. At this point the discharged sediment falls into a screw conveyor that conveys the solids to a dedicated skip for collection and disposal. Clarified liquid is collected in the tank below and transferred by the effluent transfer pump to the clients product tank.

Serviceability

The unit is constructed as a plug in portable oilfield module that can withstand rough handling. All required equipment is included and no additional purchases other than hook-up material need to be made.

Dimensions and utilities

The module is 6.0 m long x 3.6 m wide (including walkways) x 4.0 m high and a total dry weight of 7.0 mt. Wet weight is 18.0 mt. Utilities required are electrical power 60 kW. For transportation the walkways, sludge conveyor and decanter are removed so that the module can be shipped in a standard ISO 40 HC sea container. Voltage and CPS when ordering.

Download our brochure